Why Production Data Collection?

Operating a complex plant requires accessing reliable production information. In most plants, operation team captures plant’s critical data and production performance on a daily basis. Following the best practice, the captured data are then required to be verified by a team leader or superintendent.

The captured data is then used to identify Plant issues or opportunities to improve plant performance. Commercial team will as well benefit from the collected data as input to month end reconciliation process.

Also, collected data and post processed information are consequently fed into weekly, monthly and annually management reports for short- and long-term business planning. That’s why, it is crucial to have a single source of data to measure, understand, control and eventually improve plant’s reliability and KPIs.

What’s Wrong Now?

Plant Operation and Maintenance teams as well as management team are fully aware of the importance of collecting production data and consequent post processing. However, in the lack of having a suitable and reliable system, they usually develop Excel Spreadsheets to perform required analysis over the manually entered production data.

These developed Excel based systems are usually separately managed and maintained to assess production performance and gain/loss tracking.

There are three main issues with this approach:

- Human errors during manual data processing,

- Very time-consuming task to perform analysis, and the most important problem,

- Multiple sources of information for management reports.

Multiple sources of information in separate Excel based systems dramatically increases the risk of inaccurate information flow into management reports which could result in wrong decisions and eventually poor business performance.

How PIMS Can Help!

We understand that it is crucial for a production plant to have single source of information that provides accurate representation of plant performance for better decision making. PIMS provides you means to capture and analyse production data almost instantly, making the information readily available for all stakeholders (operation, maintenance, engineering, finance, management and other teams).

PIMS is a central system to collect verified data in order to produce customised and specific reports automatically to provide all stakeholders reliable and consistent information.

How PIMS Works!

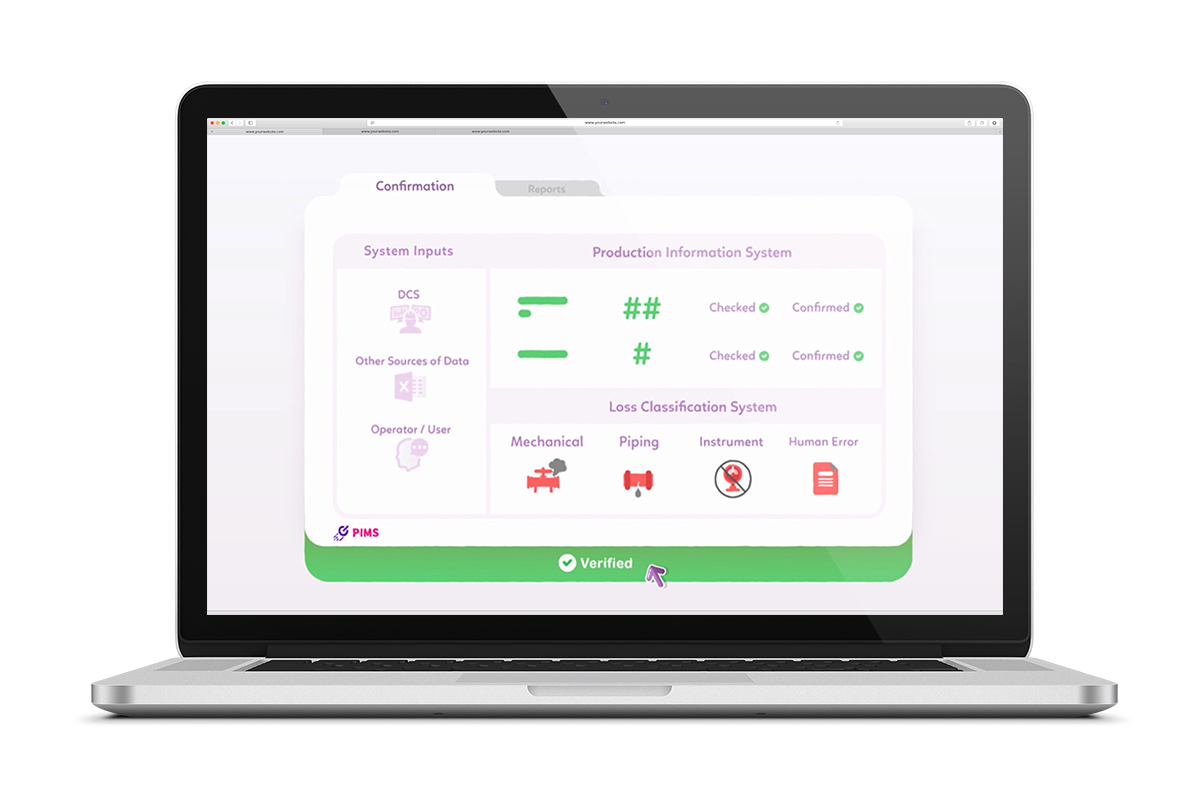

PIMS is an integrated application that provides you with an automated production information and loss classification system.

Having PIMS connected to your Plant’s monitoring system, it collects data from pre-defined Plant’s instruments. PIMS also accepts customised formulas to calculate KPIs.

Team leader or operation superintendent can then easily review and update calculated KPIs and production information before committing to record them in the database. They can modify and add comments to each calculated parameter as required.

After confirmation of data, all other users will have access to the verified data, guaranteeing single source of information to all users.

After confirmation of data, either of the modules defined below can be used to further analyse verified data.

There are two major modules in PIMS.

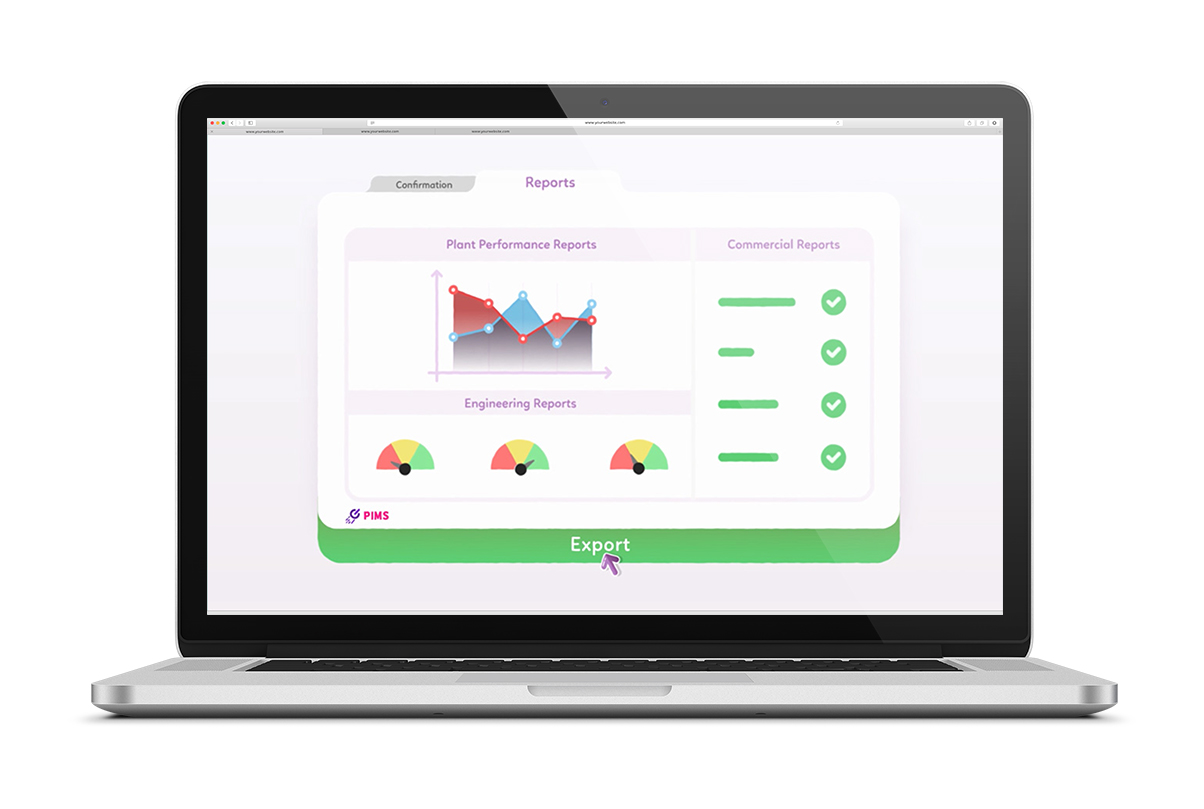

- PIMS-PRS: After confirming the calculated parameters, this module will generate multiple types of graphs and reports. In addition, users have access to download verified data to generate other customised reports using single source of data

- PIMS-PLCS: A simple classification module allowing yoe production loss causes, providing you with the best statistical recommendations for your plant improvements plans.

You want more?

You want more?

We are open to any suggestions and customisations of applications we develop. If you require specific function in the system, we are more than happy to assist. Please contact us to discuss further.

Leave a Reply